The Big Picture

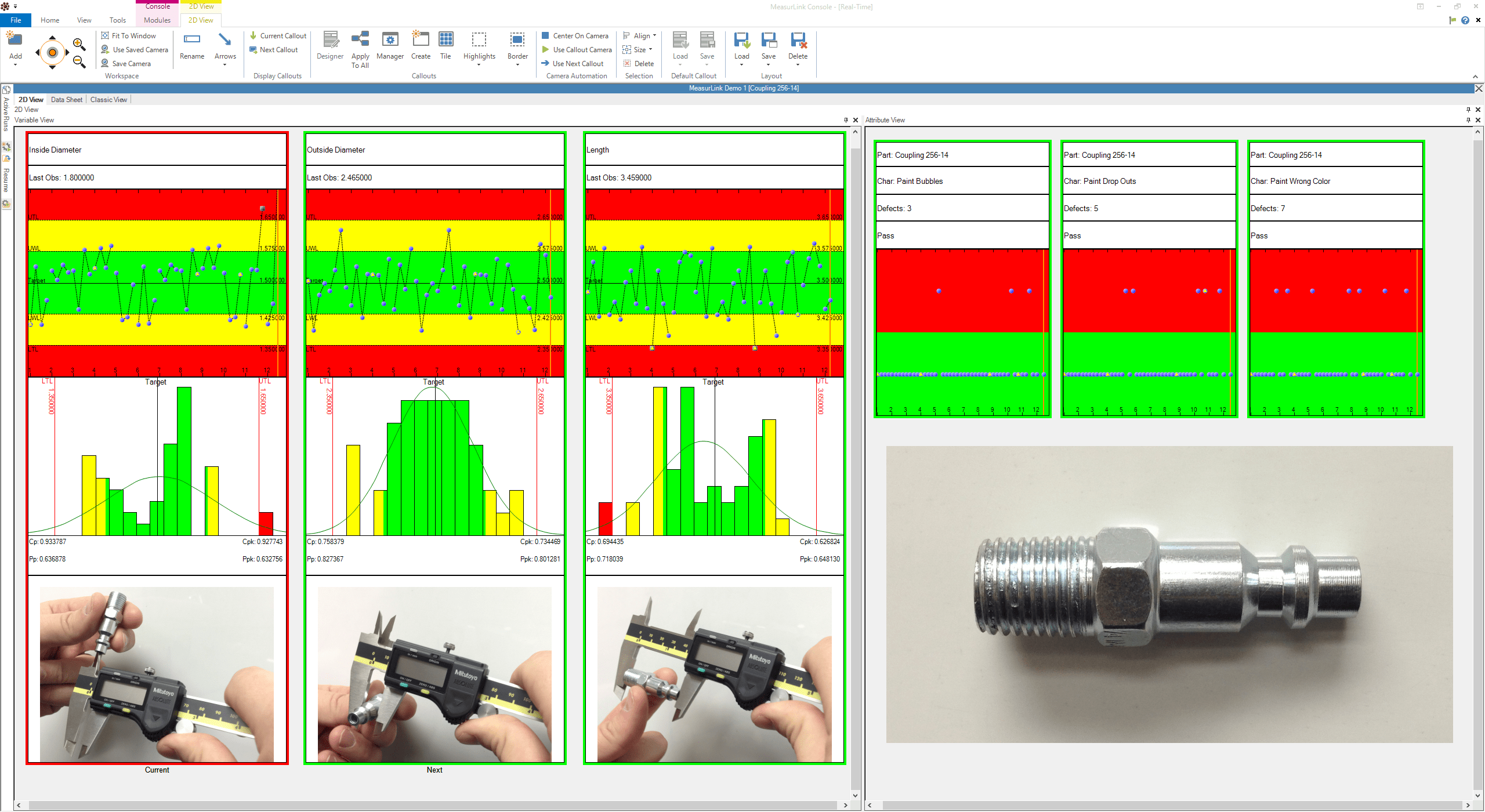

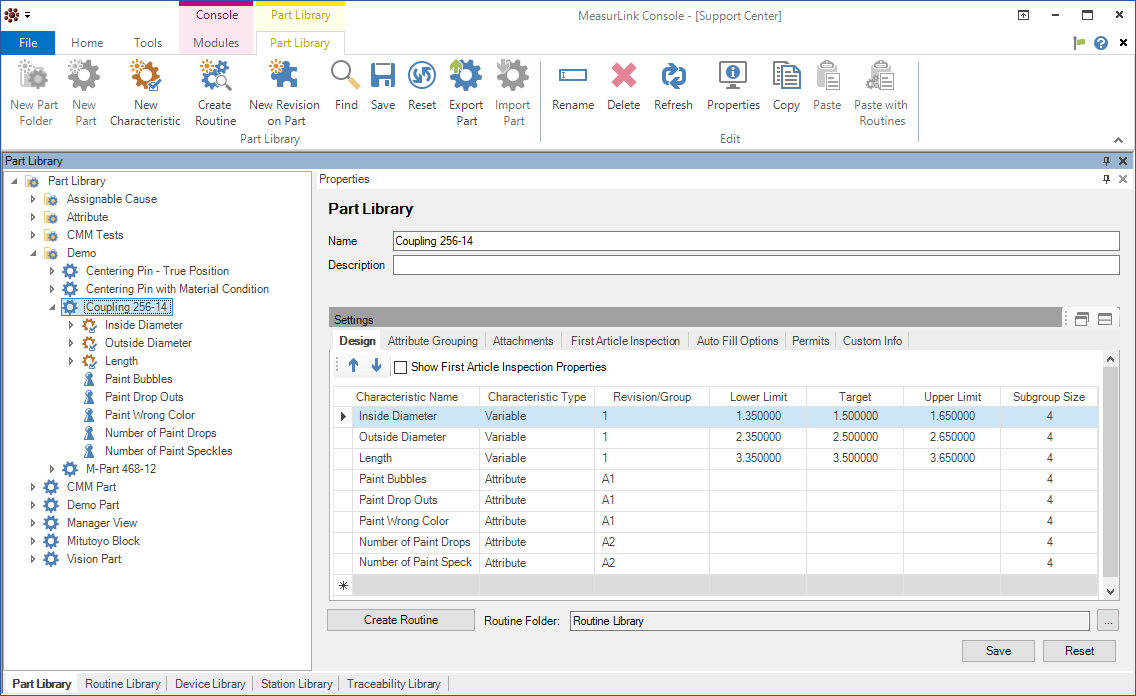

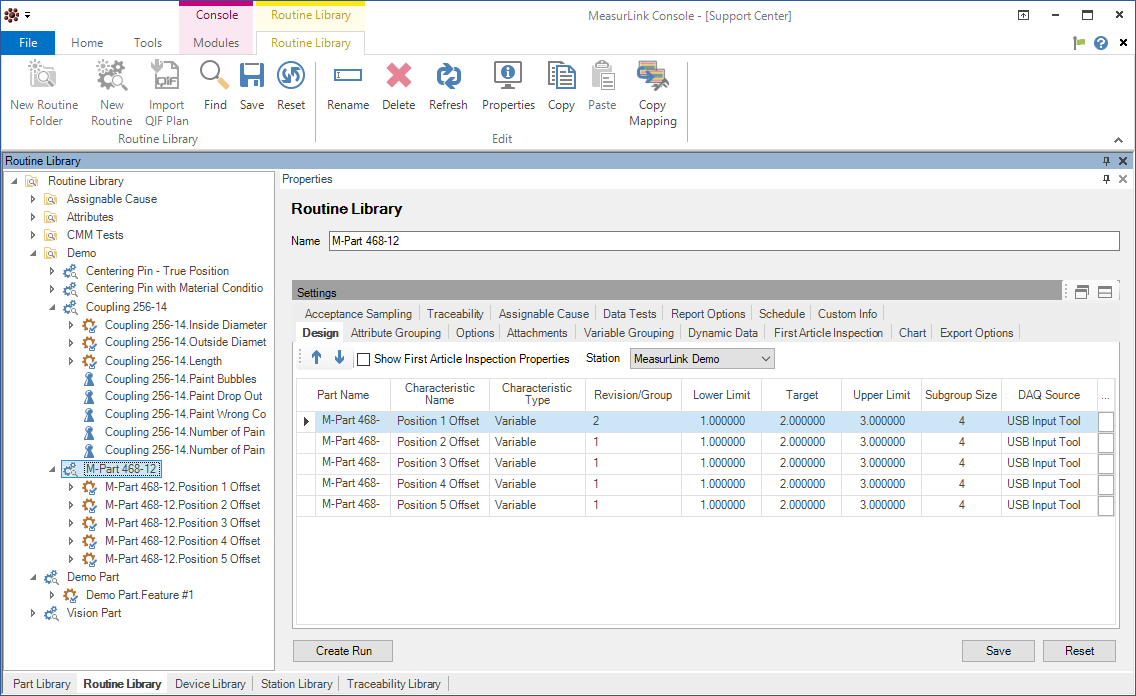

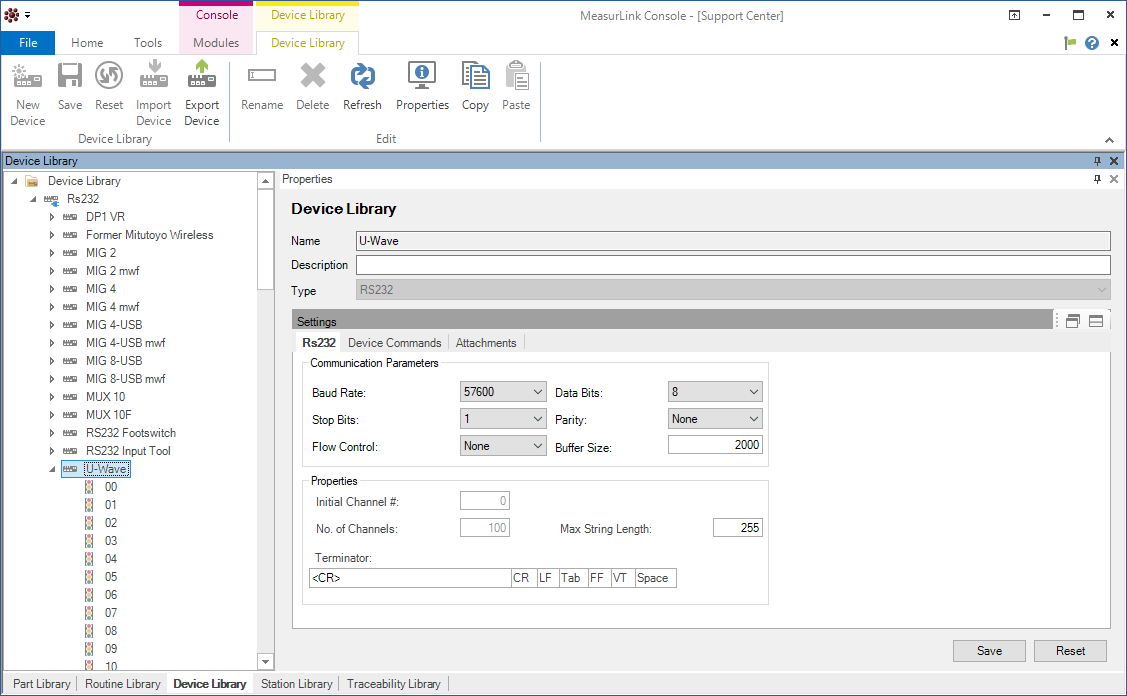

Scalable Data Acquisition, Management & Analysis

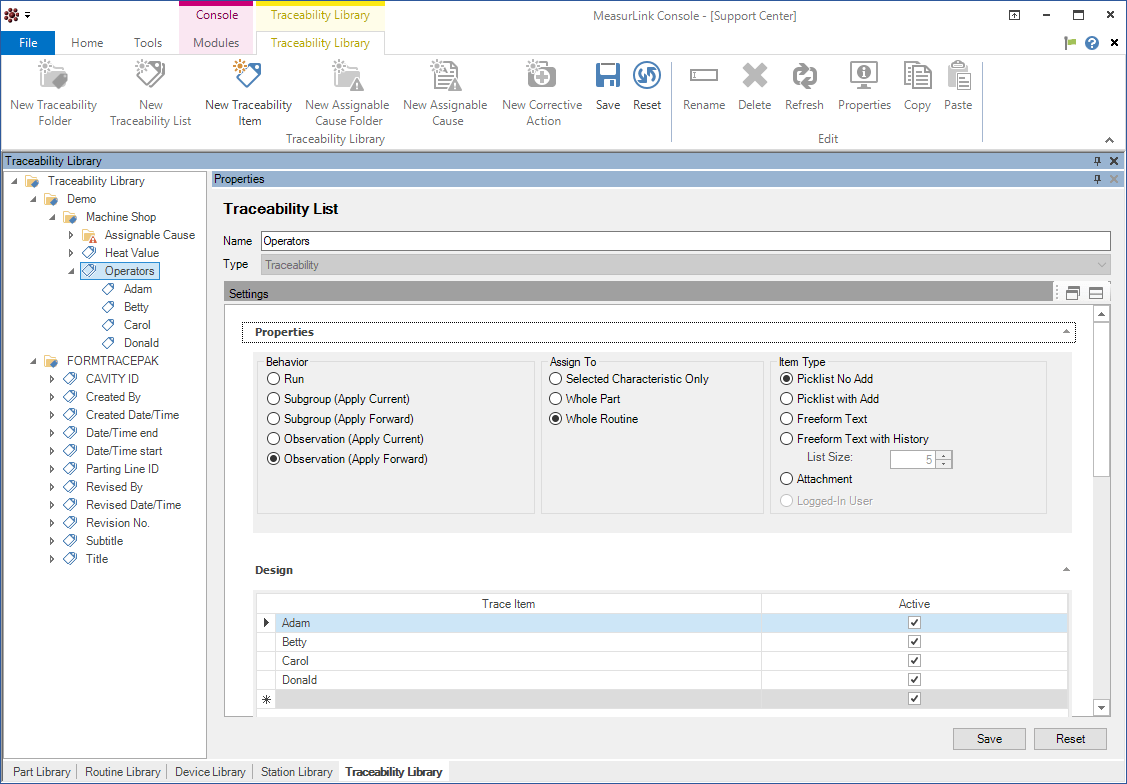

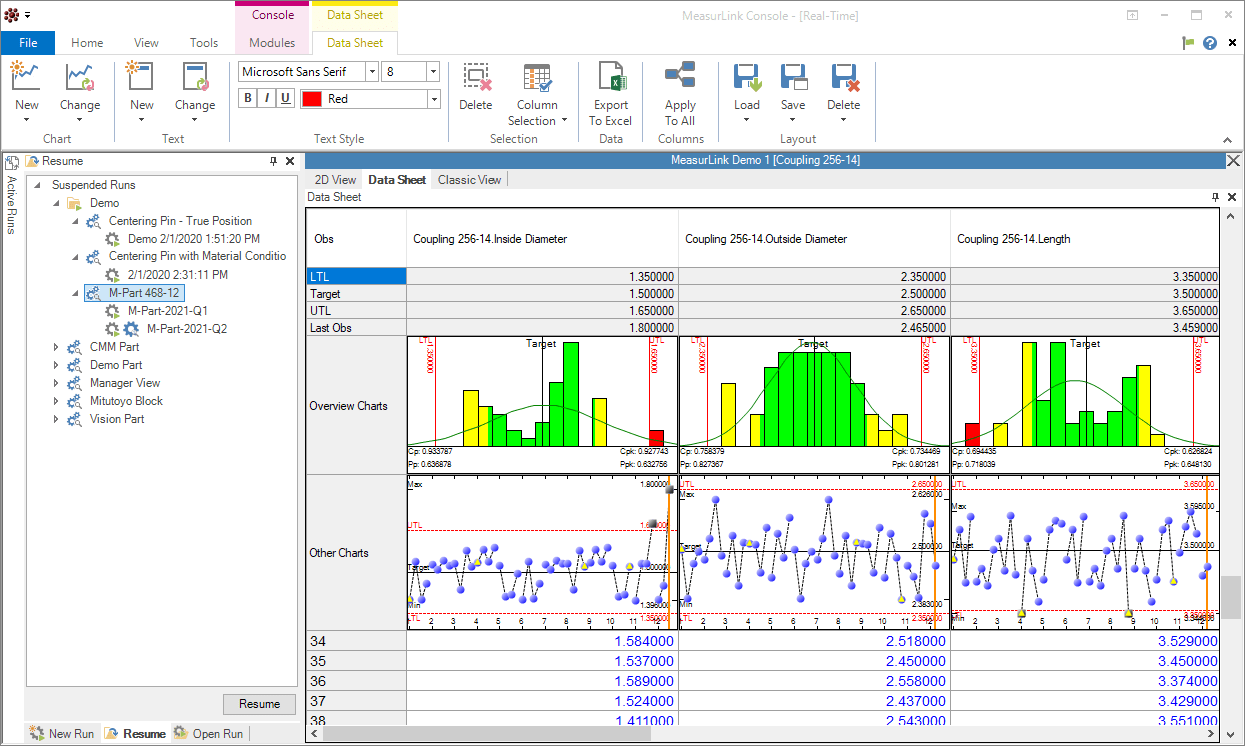

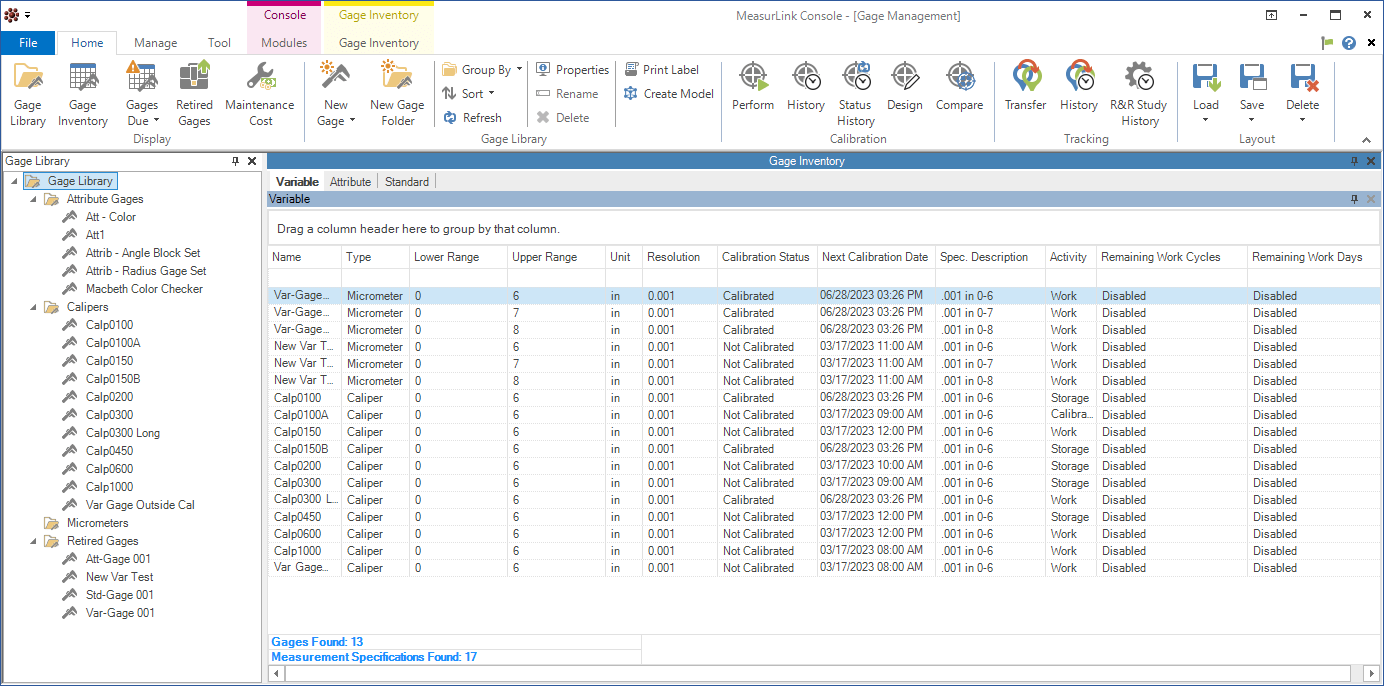

Mitutoyo has been developing MeasurLink and serving manufacturing quality programs for more than twenty years. It represents the design input of industry experts and thousands of manufacturers across the globe. It is quality inspection, management and analysis software built on a technology platform for the most robust performance and reliability. MeasurLink can serve the smallest shop to the largest multi-national enterprise with the most ease of use and power available in SPC software today. It is designed with Industry 4.0 and Smart Factory in mind and provides the scalability, extensibility and interoperability you need in your future factory!

View Our Software