Aerospace Industry Realities

Specialty raw materials and aerospace subcomponents can be expensive. Finding defects late in production increases scrap and rework along with shipment delays. Quality managers need to proactively prevent defects by monitoring processes closely at the earliest production stages. See how MeasurLink is driving innovation forward in the aerospace and defense industries.

Request a Free Demo

Data Visibility

Our customers gain the biggest improvements and cost savings by evaluating statistical data from a higher level—comparing performance across plants, processes, shifts, parts, and lots to find the next biggest opportunities for reducing costs and minimizing waste. All quality data collected by MeasurLink is stored in a single networked database, allowing users to:

- More closely monitor and analyze processes

- Prioritize quality improvement efforts

- Deliver continuous process improvements

- Generate reports and analytics

- Compare production line capability

- Ensure product consistency

AS9100 Conformance

AS9100 requires a great focus on establishing and complying with design requirements. MeasurLink uses a Part, Routine and Characteristic structure that allows users to build and maintain a system to ensure the customer’s design requirements are being inspected and held to conformance.

AS9102 describes the details for first article inspection while AS9103 defines the expectations for statistical process control. Multiple Routines, or the use of Variable Inspection Frequency along with Real-Time SPC, allows the user to ensure these inspection requirements are met.

The Defense Industry

Accurate production of defense applications, both mechanical and electronic, is life-critical. Not only are military operators at risk, but so is the success of the entire mission. Meeting stated standards for production quality and safety is a major challenge, but failing to do so can’t be an option.

Strict Governmental Standards

Defense manufacturers have no shortage of documented standards to adhere to: ISO 9001, AS9100 and its derivatives, ITAR compliant and more. The most accurate and reliable defense metrology solutions are needed to make sure that each component is fully in compliance.

Budgetary Restrictions

Strict budgets are nothing new to defense manufacturers, but that doesn’t mean standards can be allowed to slip. Manufacturers face a tough challenge: maintaining the highest level of accuracy, while still producing quickly, efficiently and at a lower overall cost.

Our Expertise

MeasurLink has been setting international standards in traceability and calibration for decades. These standards are achieved through NIST traceability supporting metrology processes, seamless integration of hardware and software, and industry-leading solutions of measuring advanced or composite materials.

Defense Metrology

Our Solutions

The Mitutoyo advanced contact and non-contact metrology solutions along with data management from MeasurLink bring unmatched precision and quality insight to virtually any defense or aerospace application, from military vehicles to high-tech applications and beyond.

MeasurLink is a critical component to LOTAR (Long Term Archival and Retrieval) as is required by many aerospace manufacturers to ensure data integrity and maintenance of quality data for the life of manufactured components.

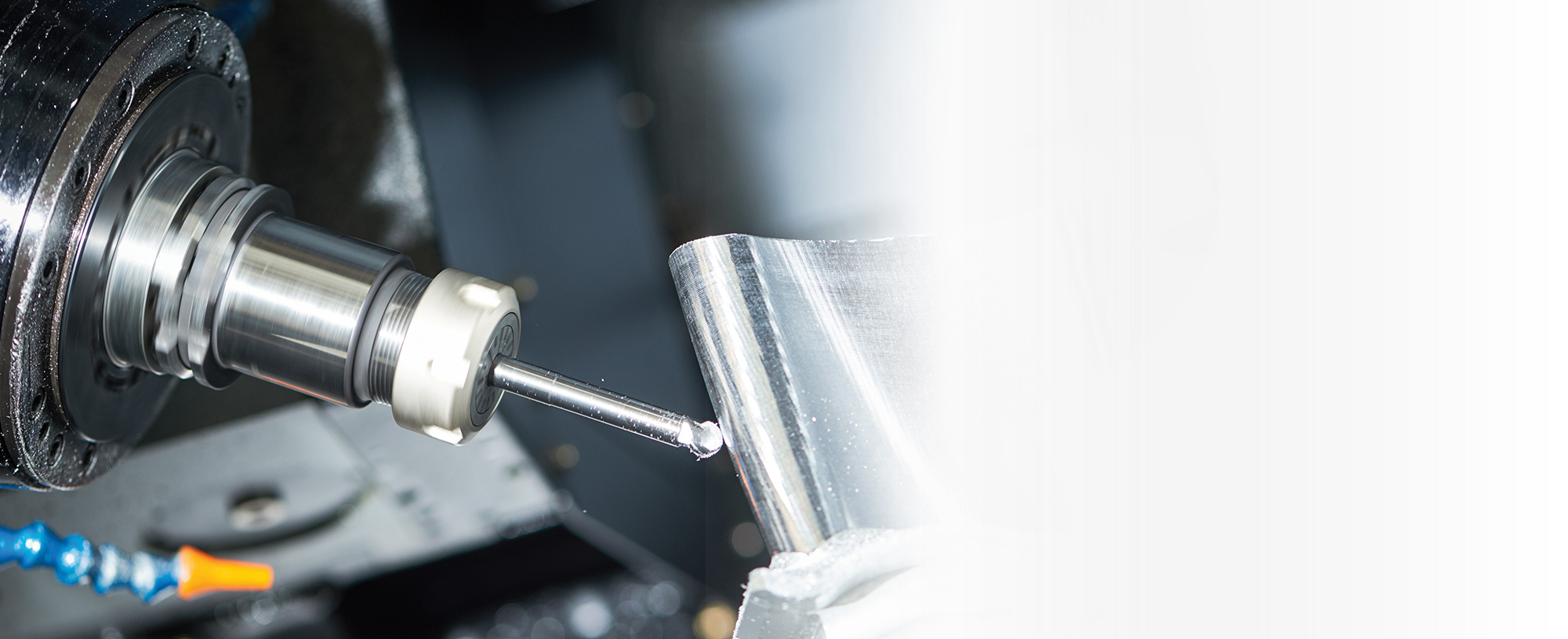

CNC Inspection

MeasurLink supports Mitutoyo’s wide array of CNC CMM, Vision and Form solutions that offer multiple sensor support and ultra-high accuracy — ideal for the diverse components in a mission-critical military application.

Coordinate Your Metrology Solution

We are more than just a metrology supplier — we aim to be your true partner. If your application requires a metrology solution beyond what’s available off the shelf, our Custom Solutions Group will work with you to meet your needs. From custom fixtures to advanced integration, accessories or full solutions, we will make sure your metrology process is set up for victory.