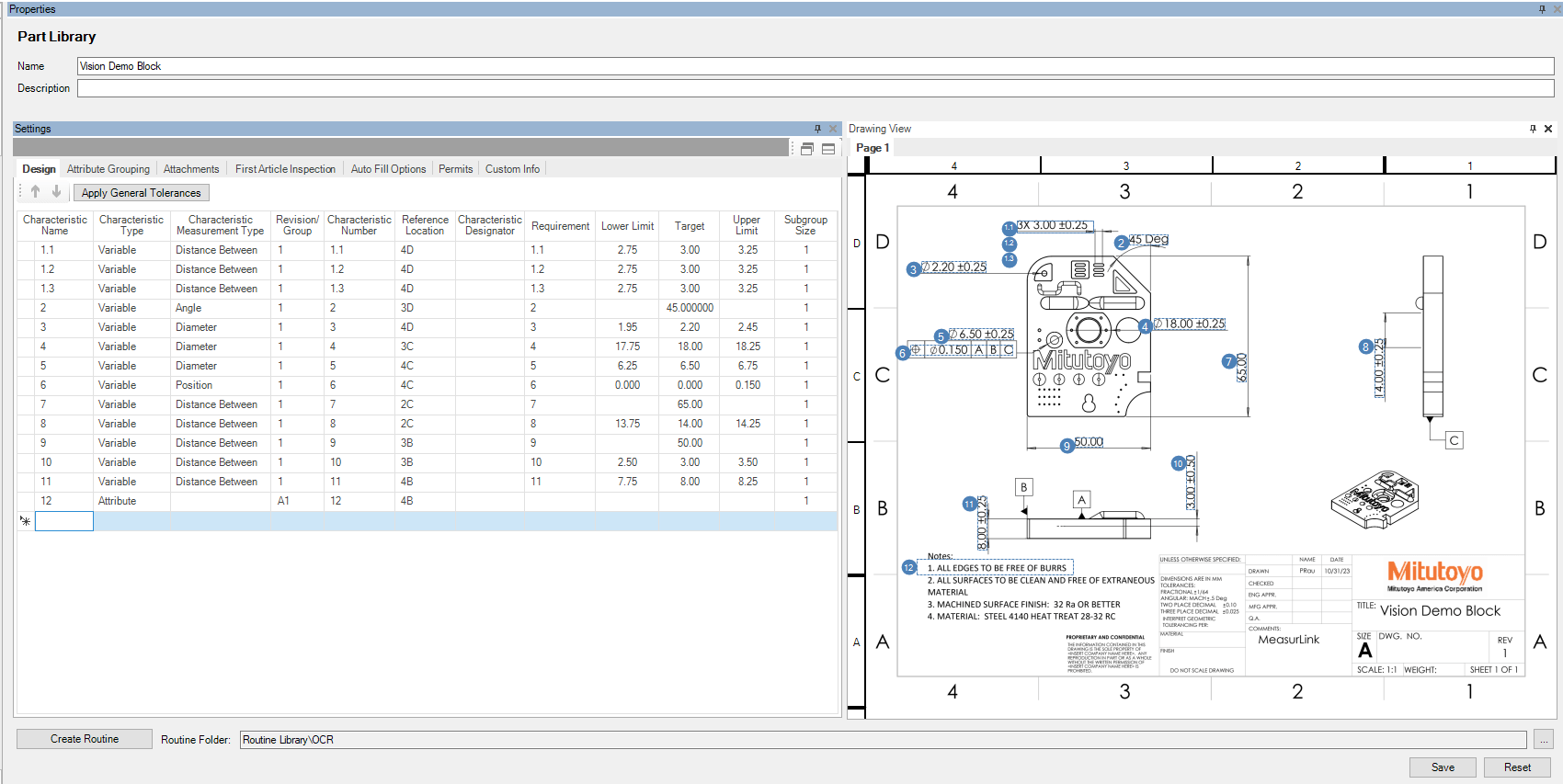

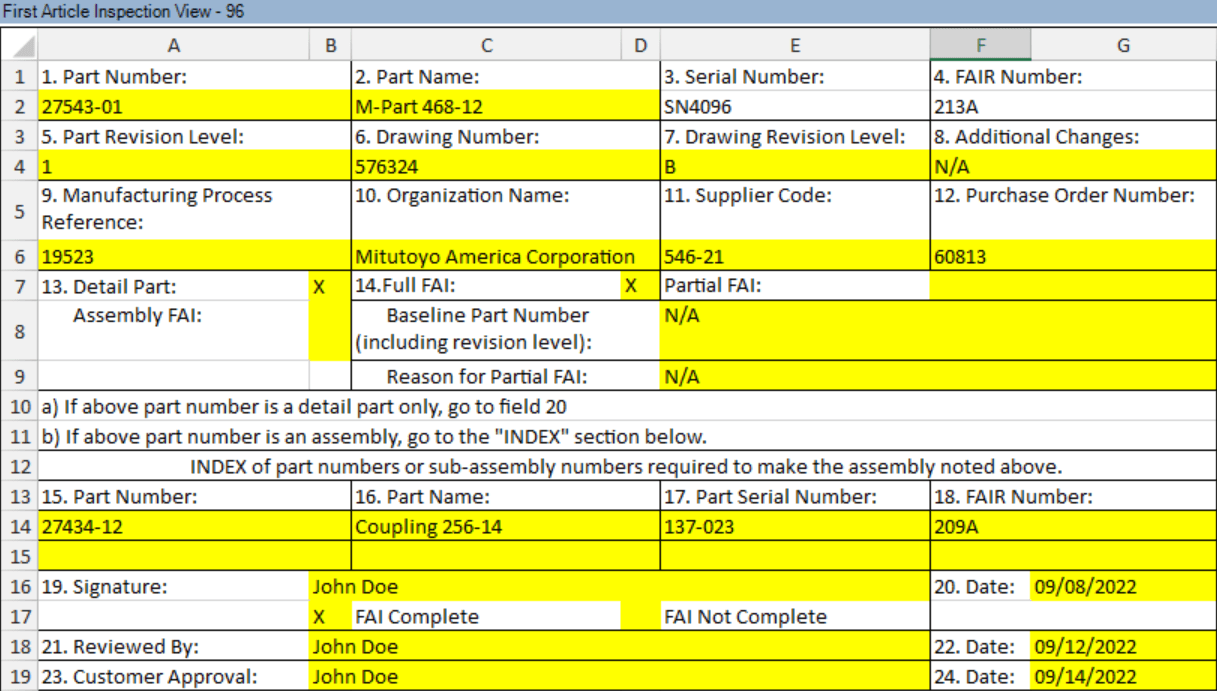

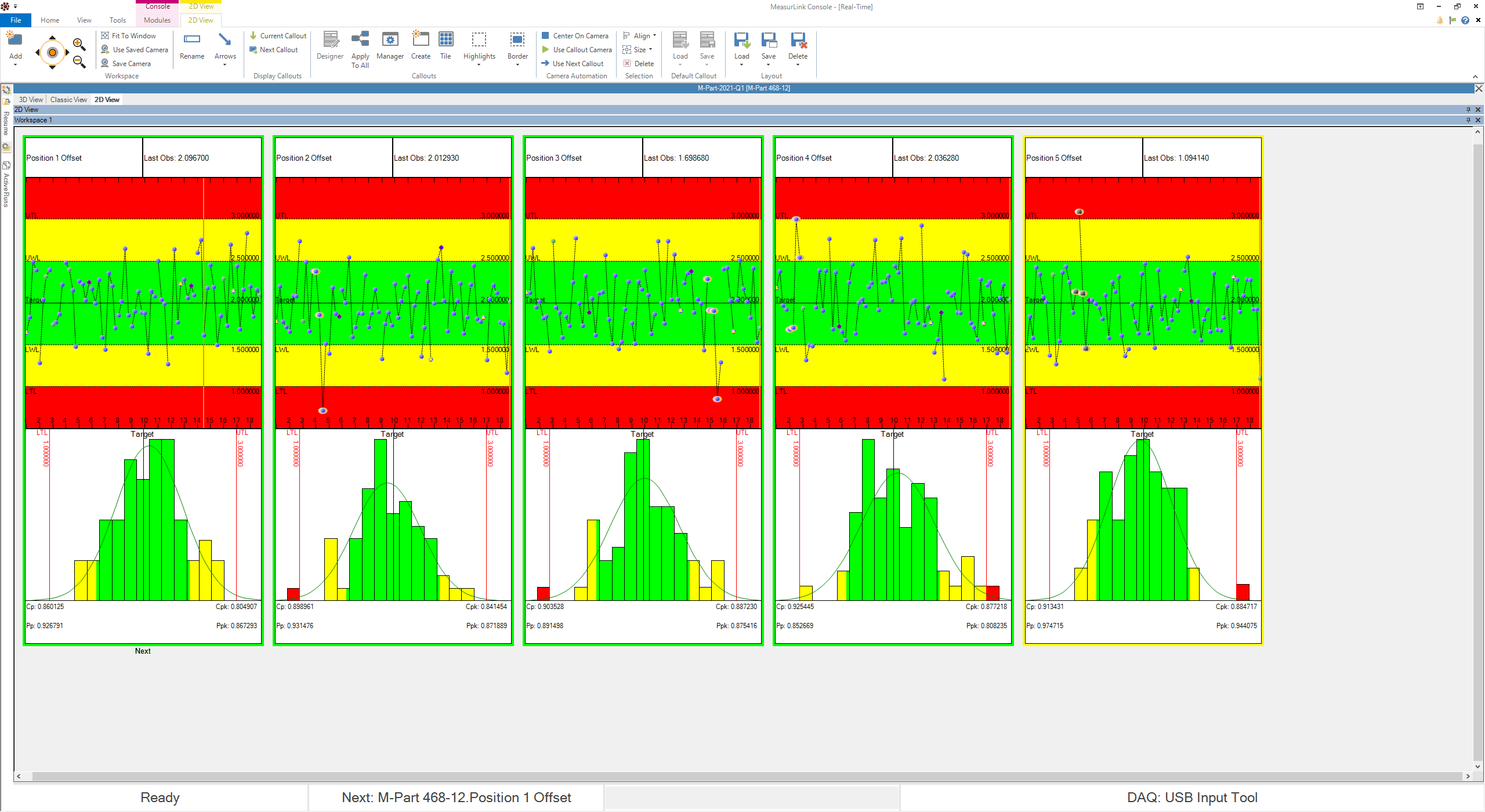

2D Print Scanning

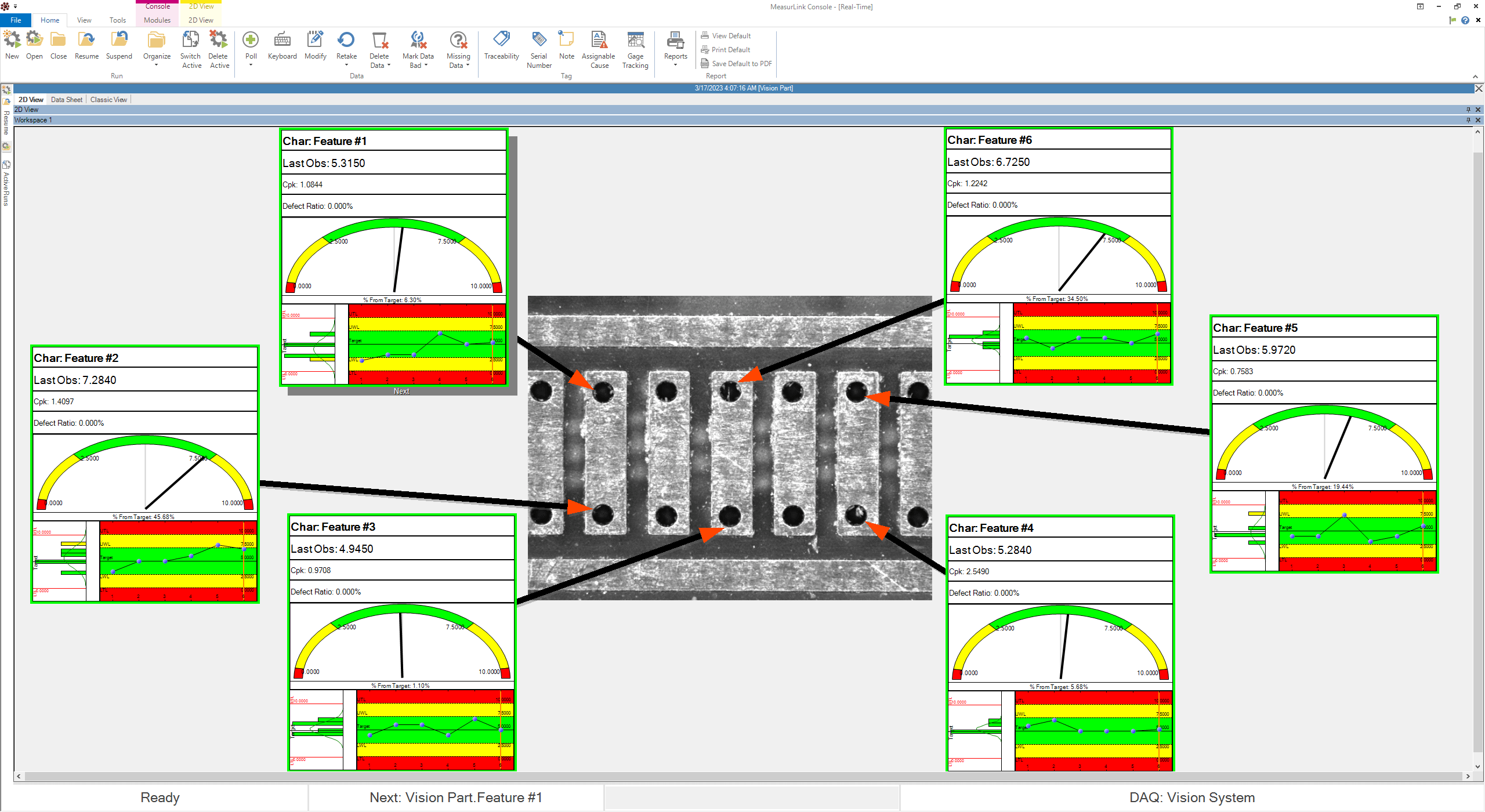

2D prints can be scanned, using OCR technology, in order to assist in creating a new part, ballooning the drawing and populating tolerances. A ballooned image of the original print can be saved and used in Real-Time behind callouts in the 2D View.

View New Features