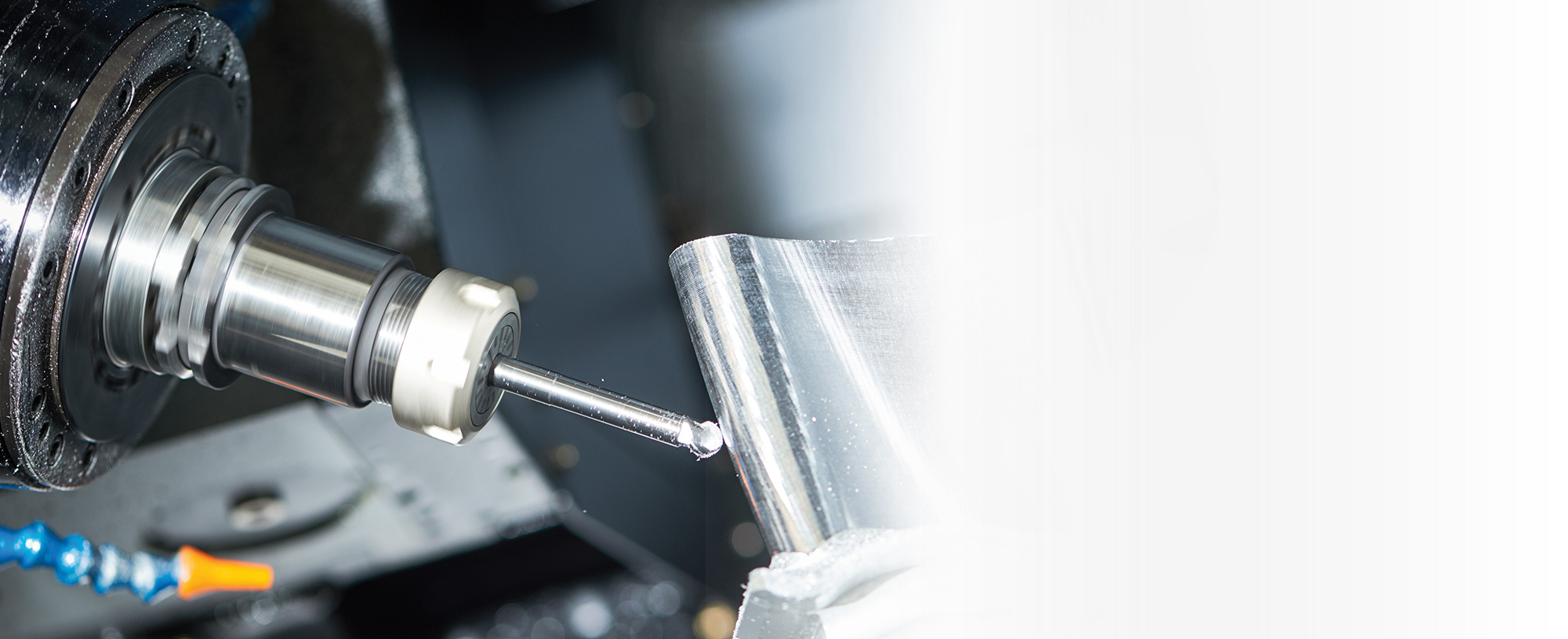

Machine Tooling Realities

No two machining applications are the same. From standard lathes and milling machines to multiple access machines, cutters and lasers, each machine tool comes with its own challenges for traceability and repeatability. What’s more, these measurements must be accurate, consistent and fast. See how MeasurLink is driving change and innovation in the general manufacturing industry.

Request a Free Demo

Efficiency Pressures

Faced with budgets and high demand, manufacturers attempt to reduce costs by speeding up production cycles and increasing throughput. However, this can lead to mistakes that have serious consequences, since error-ridden products require costly reproduction.

Industry Variations

Factory-floor applications of nearly every shape, size and space play a major role in countless industries. These industries measure diverse factors like roundness, roughness, hardness, length — or even multiple factors throughout the production process. Without an integrated, full-scope metrology solution, critical errors are possible.

Data Import & Export

XML / ASCII Import & Export

MeasurLink is a core software when implementing intelligent manufacturing. The Real-Time module can collect or import data from many sources including quality information format (QIF), text, ASCII, CSV, XML data sources, serial devices, USB and virtual COM ports.

Our Expertise

Efficient Solutions

We partner with global manufacturers in a wide range of industries to deliver perfectly calibrated, reliable metrology solutions for machined products. Our efficient solutions run the gamut of metrology applications, allowing practically any manufacturer to rapidly ensure quality.

- Certified traceability to NIST standards

- Full range of solutions: in-line and offline, contact and non-contact

- Coordinated software for efficient data storage and analysis