home / Resources / SPC / Statistics / Data Tests

Downloads

Request a Demo

home / Resources / SPC / Statistics / Data Tests

Downloads

Request a Demo

Data Tests

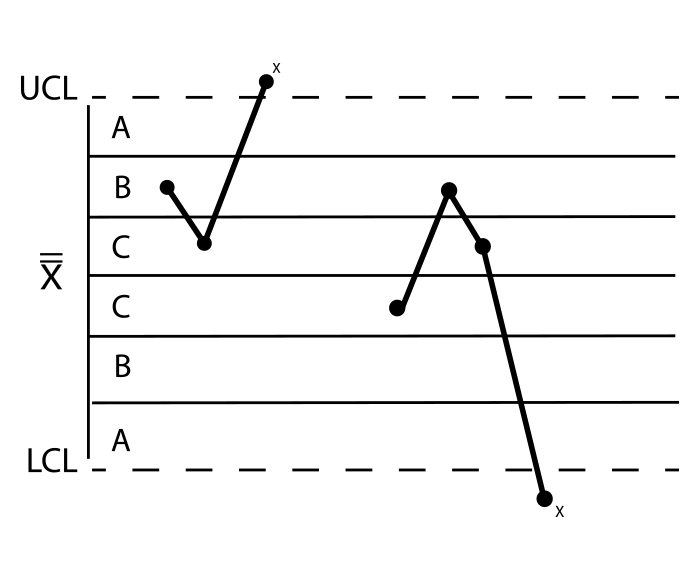

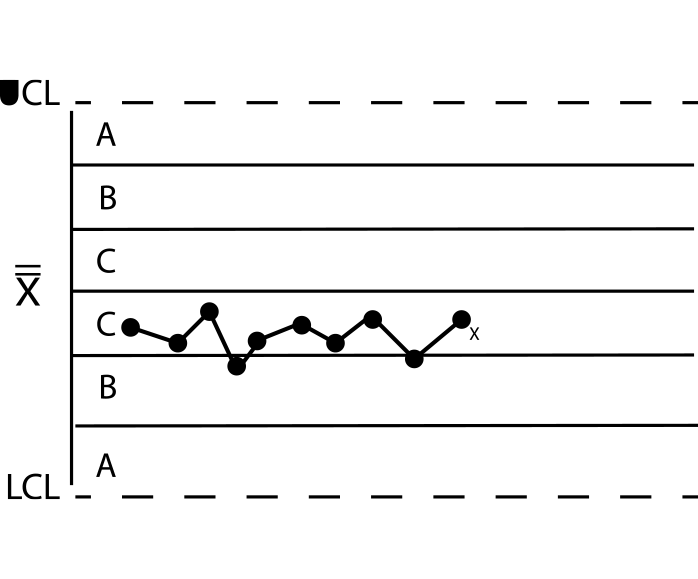

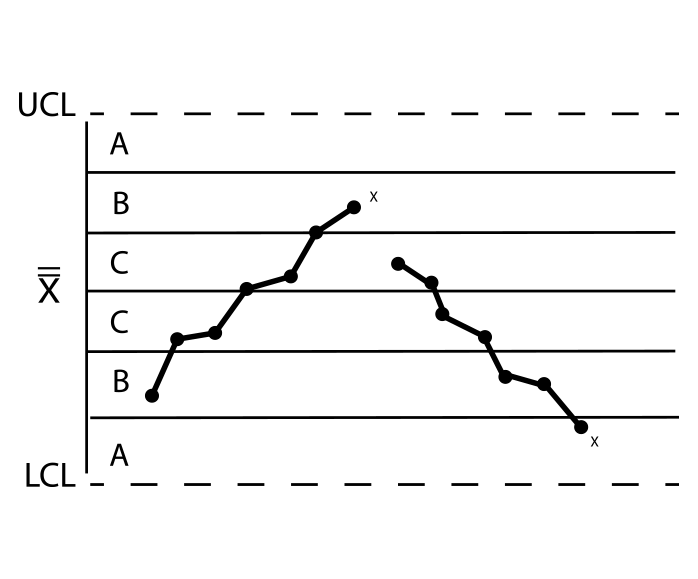

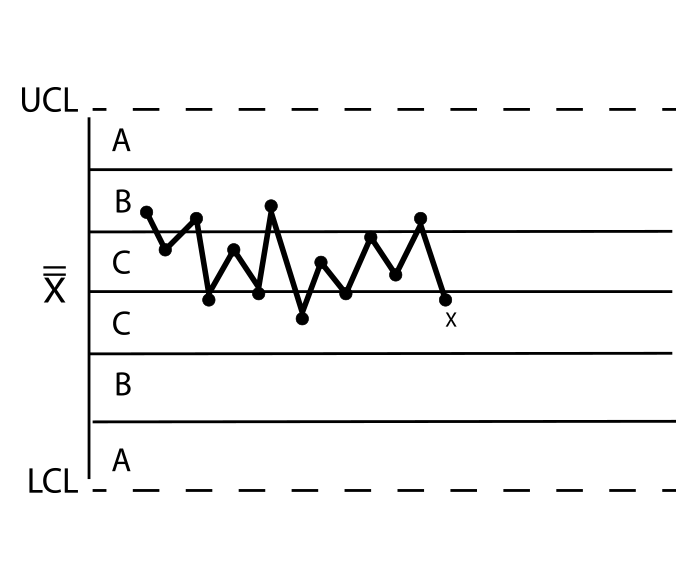

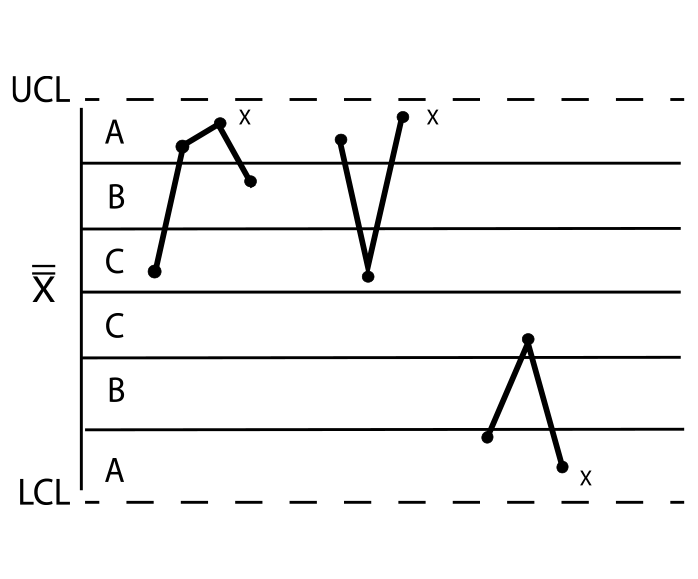

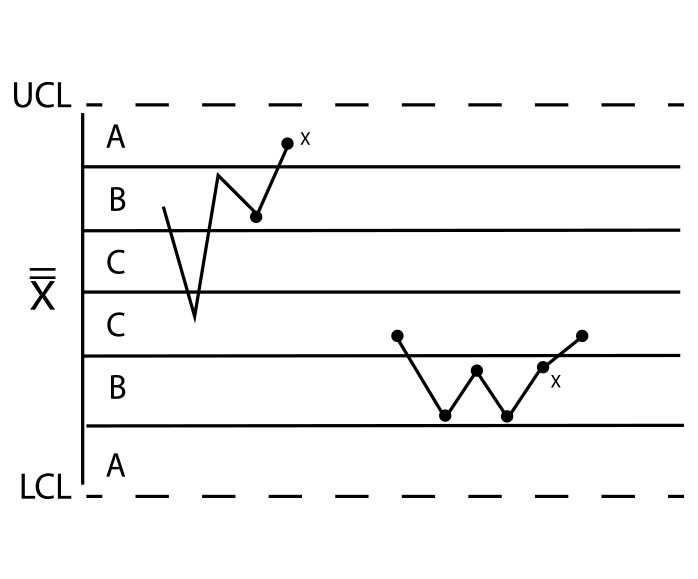

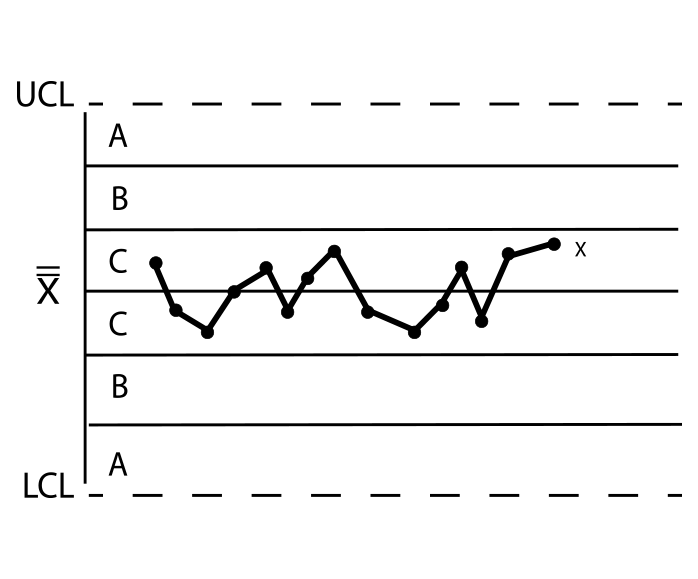

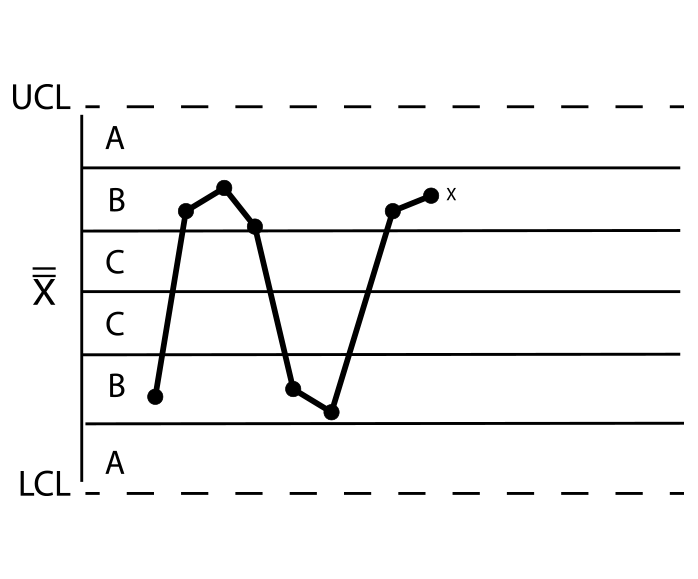

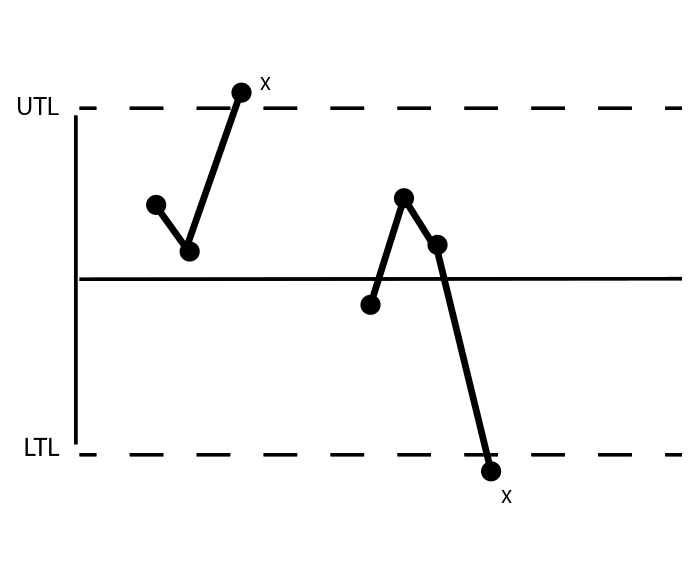

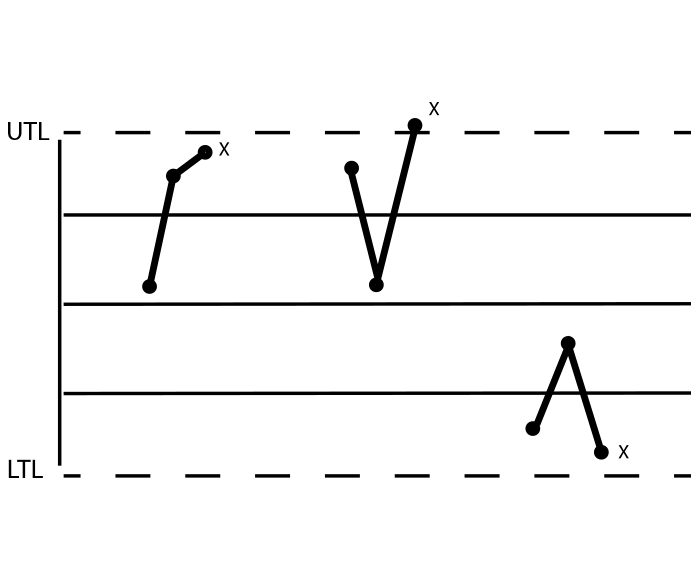

MeasurLink can check data as it is received for statistical patterns that indicate a change in randomness. A change in randomness can indicate that the manufacturing process has changed from its initial settings. The initial settings are designed to create the best Part possible, so when the system deviates from the initial settings the manufacturing process has moved off its optimum settings.